Whilst Swiss turning is usually a core competency, Nanotech Precision has abilities for introducing micro characteristics to Swiss-machined medical parts applying micro laser, micro EDM, or micro wire EDM abilities. This is certainly a significant differentiator during the Swiss clinical machining realm.

“Within the 1 hand, we recognize the attempts taken by our associates so far to disrupt Russian supply chains,” explained Vladyslav Vlasiuk, a sanctions qualified and adviser to Ukrainian President Volodymyr Zelensky. “Concurrently, it truly is clearly not enough.”

This produces an electrical arc among the electrodes, elevating the temperature with the tool electrode and melting the metal.

The aerospace industry has a long-shared historical past with CNC machining. The machining of metal aircraft components occurs at the best degree of precision.

CNC automation enables electrical discharge machining (EDM) in two techniques. It makes it possible for vertical EDM requiring electrodes with a similar shape and size as being the cavity being carved out.

He didn't reply to observe-up questions on irrespective of whether his firm equipped equipment to your manufacturing facility at any place.

CNC milling is really a subtractive manufacturing method that takes advantage of rotary cutters to remove content from your workpiece. The way, angle, force, and cutting tool velocity could vary to build various cutting outcomes.

Powder coating: The plastic powder is adsorbed to the surface from the workpiece by electrostatic spraying to sort a powdery coating, and afterwards the powder layer is cured by heating and baking to stage it into a uniform movie layer. It is usually used for physical appearance parts, and several different colours is obtainable.

But pretty wonderful get more info attributes and tight tolerances are tougher to realize manually, and this is where a pc-managed program pursuing a electronic blueprint really arrives into its possess.

The main target might be on increasing the performance and dependability of energy technology equipment, as well as reducing the environmental effects of manufacturing processes.

Anodizing: A technique of forming a layer of oxide film on aluminum items, to overcome the defects of aluminum alloy area hardness and wear resistance.

Nevertheless, in most cases, a concluded product or service designed making use of precision machining doesn't need any secondary processing.

Pc-Aided Layout makes a graphical representation of your part within a digital structure. This illustration is not hard for the designers, operators, and companies to be aware of. However, CNC machines used to make the element tend not to fully grasp this electronic structure instantly.

Yet another benefit of Nanotech Precision Swiss machining is the opportunity to finish complex parts in a single setup. Nanotech makes use of very adaptable machine tools with approximately 10 managed axis that will machine features from any angle or course, all although protecting control of the machined ingredient. Remarkably complex swiss machined parts and components are prevalent at Nanotech Precision.

Mr. T Then & Now!

Mr. T Then & Now! Amanda Bearse Then & Now!

Amanda Bearse Then & Now! Elisabeth Shue Then & Now!

Elisabeth Shue Then & Now! Lacey Chabert Then & Now!

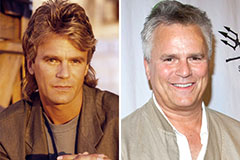

Lacey Chabert Then & Now! Richard Dean Anderson Then & Now!

Richard Dean Anderson Then & Now!